Often carrying valuable commodities, reefer trailers must cover thousands of kilometers over extended periods. These products have tight temperature requirements, hence any variation can compromise their safety. Therefore, the main attention of the driver inside the trailer is the temperature control system; hence, guaranteeing stable and correct operation of the equipment is absolutely important. How therefore can you guarantee a travel free of worries? Apart from being generally dependable in quality, a trustworthy trailer refrigeration unit also depends on correct use and maintenance. Every one of these processes is equally crucial.

Daily Inspection Items for Trailer Refrigeration Units

Inspect the condenser and clean any debris on the rooftop condenser in a timely manner to ensure proper airflow.

Check the fuel tank to ensure sufficient fuel, and drain water from the tank approximately every six months.

Inspect the unit’s belt by pressing the middle part of the belt with your thumb. The belt should bend between 6mm and 13mm. If it exceeds this range, the belt should be tightened.

Check the unit’s battery to ensure it is securely fixed to the bracket, and the positive and negative terminals are properly connected to the wiring harness.

- Engine Compartment Check:

Inspect the engine compartment, pipelines, filters, engine, and compressor for any visible leaks or fluid seepage. Ensure the engine oil level is at the midpoint of the dipstick, and the compressor refrigeration oil level aligns with the center mark of the sight glass.

Check the coolant to confirm there is coolant in the expansion tank above the right-side door of the unit.

Regular Maintenance of Trailer reefer Units

Engine Oil— The recommended engine oil should meet the American Petroleum Institute (API) standards. These API grades are developed for lubricants designed for various diesel engines operating under different conditions.

It is recommended to use commercially available engine oils that meet the following standards:

- EMA DHD-1 Multi-Grade Oil

- API CH-4 Multi-Grade Oil

- ACEA E5

Key Notes:

- Non-compliant oils may adversely affect engine performance.

- Using oil with the correct viscosity is critical. The table below specifies viscosity grades for different ambient temperatures.

Engine Oil Level Inspection Procedure

Run the unit until the engine reaches operating temperature, then shut it down.

Remove the dipstick, wipe it clean, and fully reinsert it into the oil tank to ensure proper seating.

Withdraw the dipstick again and check the oil level:

If the level is within the safe range (marked on the dipstick), no refill is required.

If low, add oil until the level reaches the upper limit of the safe range (as indicated by the dipstick marks).

Conclusion

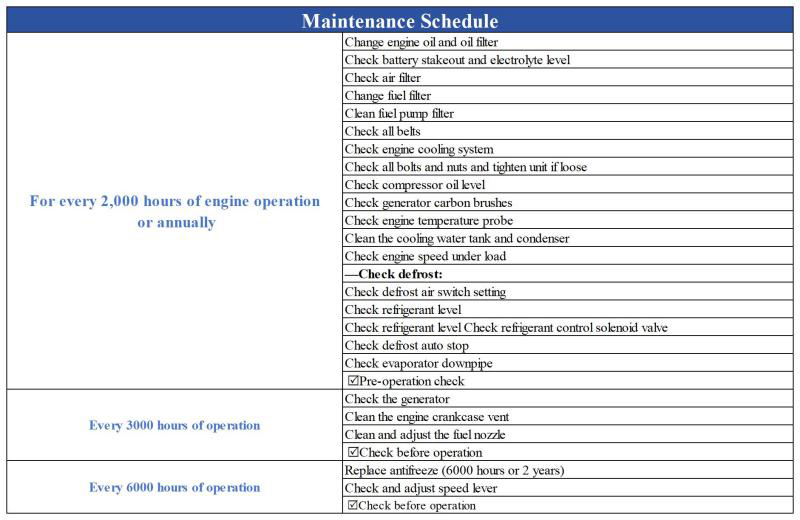

Regular inspections and systematic maintenance not only extend the service life of your trailer refrigeration unit but also safeguard cargo integrity throughout every transport. Timely upkeep effectively prevents equipment failures, minimizes downtime, and ensures uninterrupted operations. Each meticulous inspection and maintenance action establishes a robust foundation for secure cargo delivery and optimized operational efficiency. For reference, you may consult the maintenance schedule below.

.png)

.png)